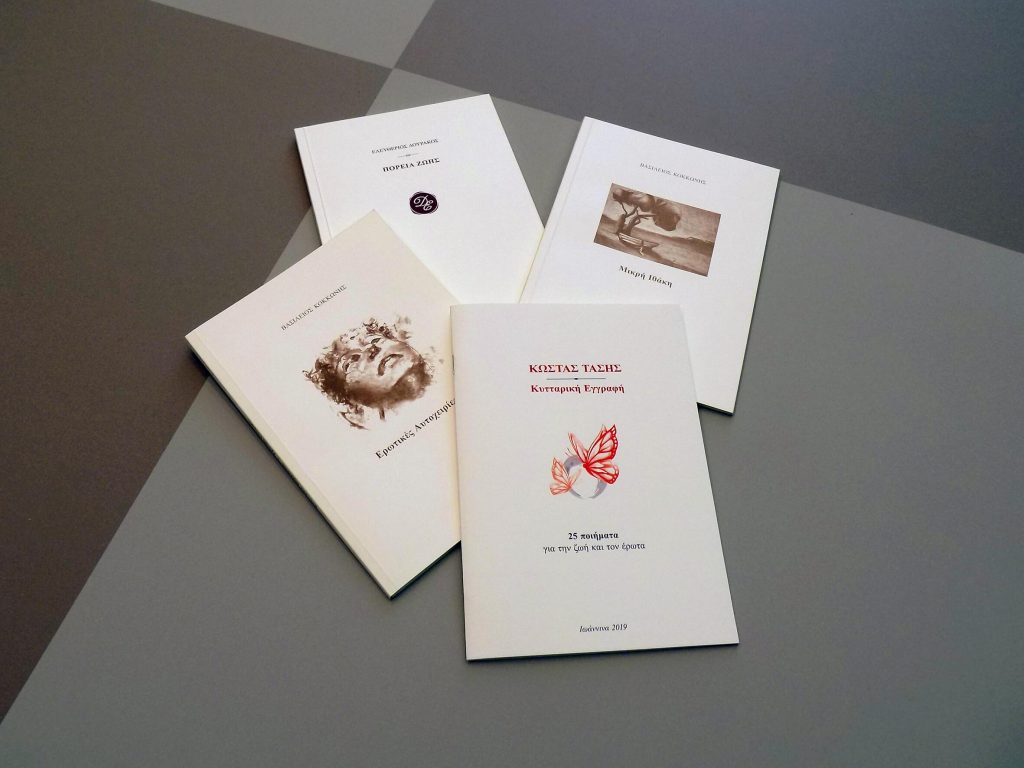

Offset printing

PRINTS OFFSET

THE Offset printing is a printing method that is used for playback texts and images. Offset relies on the phototransfer of the subject onto the surface of metal printing plates in such a way as to allow the different chemical behavior of the various areas of their surface. Modern printing plates are made of aluminum but in the past there have been zinc (zinc) plates. For this reason, the printing plates of the method are often called tins. The method is used for printing monochrome and multi-color forms and dominates the publishing-printing industry.

APPLICATIONS AND PRODUCTS

The most common forms printed with this method are: Books, newspapers, magazines, posters, brochures, envelopes, letterhead, placemats, folders.

PRINTS OFFSET & BENEFITS

Low price per piece

The more copies we print, the less we will pay per piece, since most of the cost is pre-press.

Excellent quality

Printing produces rich, accurate colors and high-quality images and photos, with clear fonts and fine details visible.

Various papers

A wide variety of paper types with special finishes can be used.

Special inks

Custom inks such as metallics as well as Pantone colors are available. Premixed inks can also be used in printing. It also offers a variety of different finishes such as the application of varnishes (matt/glossy).

Samples

Interest Form

FAQ Offset printing

How do Offset Prints work?

Offset printing, also known as offset lithography, is one of the most common forms of commercial printing. It is widely used to produce high-quality printed materials such as brochures, magazines, books and more.

The process of offset printing involves transferring ink from a printing plate to a rubber cover and then to the printing surface (usually paper or cardboard). This indirect ink transfer is what differentiates offset printing from other printing methods.

Here's a step-by-step breakdown of how offset printing works:

-

Pre-Print: The first step is to prepare the artwork for printing. This includes designing or downloading the digital file, adjusting the colors and converting it to a format suitable for the printing process.

-

Plate making: In offset printing, the artwork is transferred onto printing plates. These plates are usually made of aluminum or polyester and contain the image to be printed. Plates are created by a process called "platemaking," which involves exposing the plates to light, developing them, and treating them with chemicals to make areas of the image attract ink.

-

Ink Application: Once the plates are ready, they are placed in the printing machine. Ink is applied to the plates and a series of rollers distributes the ink evenly over the surface of the plates. Ink only adheres to the image areas of the plates, while the non-image areas repel the ink.

-

Image Transfer: The inked plates are then brought into contact with a roller with a rubber blanket. The elastic blanket transfers the ink image from the plates onto it, retaining the image in reverse. The elastic blanket acts as an intermediary, allowing the transfer of the ink image to the final print surface.

-

Printing Surface: The printing surface, usually paper, is fed through the press at high speed. As the paper passes between the blanket roller and an impression roller, the ink image is transferred to the paper. The pressure exerted by the impression roller ensures clean and accurate transfer of the image.

-

Drying and finishing: After the ink is transferred to the paper, it must dry. Printed sheets are usually passed through a series of heated rollers or allowed to air dry, depending on the type of ink used. After drying, the printed materials may undergo additional finishing processes such as cutting, folding, binding, or other post-press treatments.

What kind of products can I print through Offset Printing?

Offset printing, also known as lithography, is a popular printing method that involves transferring an image from a plate to a rubber cover and then to a printing surface, usually paper. This process is widely used for high volume commercial printing such as magazines, brochures and newspapers.

Here's a step-by-step explanation of how offset printing works:

-

Prepress: The first step in offset printing is to prepare the artwork or design for printing. This involves creating a digital file or a physical plate with the desired image.

-

Plate construction: In offset printing, plates are used to transfer the image to the printing surface. The plate is usually made of aluminum or other metal and contains the image in relief or indentation. Each color in the design requires a separate plate.

-

Ink Application: Once the plates are ready, ink is applied to them. Offset printing uses a process called "offset" because the ink is not applied directly to the printing surface. Instead, the ink is transferred to a rubber cover, which then applies the ink to the paper or other substrate.

-

Image Transfer: The ink plate contacts the elastic blanket and the image is transferred onto it. The rubber cover is flexible and can adapt to the texture of the print surface, ensuring more even and consistent ink distribution.

-

Printing: Finally, the rubber blanket with the transferred image comes into contact with the paper or other substrate. The pressure applied during the printing process transfers the ink to the substrate, creating the final printed product.

What print sizes are available for Offset Prints?

Offset printing offers a wide range of print sizes to meet various needs and preferences. The print sizes available for offset printing depend on the specifications and limitations of the printing press being used. Here are some common print sizes used in offset printing:

-

A4 (210mm x 297mm): This is a widely used standard size for documents, pamphlets, brochures and posters. Commonly used for letterheads, displays and marketing materials.

-

A5 (148mm x 210mm): This size is commonly used for brochures, catalogs and postcards. It is half the size of A4 and is suitable for compact designs.

-

A6 (105mm x 148mm): A6 is typically used for smaller promotional materials such as invitations, brochures and notebooks. It is a convenient size for quick distribution.

-

DL (99mm x 210mm): DL size prints are often used for envelopes, brochures and shelf cards. They are long and thin, which makes them suitable for displaying information in a concise manner.

-

B5 (176mm x 250mm): B5 is a popular size for books, magazines and catalogues. It provides a larger layout surface compared to A4, allowing for more detailed designs.

-

B6 (125mm x 176mm): B6 is commonly used for pocket books, magazines and diaries. It is smaller than the B5 and is often chosen for its portable nature.

-

8.5" x 11" (Letter size): This size is widely used in North America for documents such as letters, reports, and newsletters. It is a standard size for many office documents.

-

11" x 17" (Tabloid Size): Tabloid size prints are often used for larger posters, brochures and newspapers. It provides greater visual impact due to its larger dimensions.

These are just a few examples of the print sizes available for offset printing. It is important to note that specific print sizes may vary depending on the printing company and the capabilities of the printing equipment.

What is the difference between Offset Printing and other printing methods?

Offset printing is a traditional printing method that has been widely used for decades. It involves transferring ink from a plate to a rubber cover and then to the printing surface. This process is called offset because the ink does not come into direct contact with the paper.

One of the main advantages of offset printing is the high quality of the image. Produces sharp and clear prints with vivid colors and fine details. This makes it ideal for printing materials such as brochures, catalogues, magazines and posters.

Offset printing also offers a wide range of paper options. It can handle various paper thicknesses and finishes, allowing for greater customization and flexibility in print projects. In addition, offset printing can effectively reproduce large prints, making it a cost-effective option for mass printing.

On the other hand, other printing methods such as digital printing have gained popularity due to developments in technology. Digital printing involves transferring the image directly from the computer to the printing surface, eliminating the need for plates. This makes it a faster and more convenient choice for small and print-on-demand.

Digital printing also offers variable data printing, which allows for the personalization and customization of each printed piece. This can be especially beneficial for direct mail campaigns and targeted marketing efforts.

Although digital printing may not reach the image quality of offset printing for long runs, it has seen significant improvements over the years. Many digital printers now offer high-resolution output that is comparable to offset printing in terms of quality.

In terms of cost, digital printing is often more cost effective for small runs as there are no upfront costs for plates or set-ups. However, as print volume increases, offset printing becomes more economical.

Last Updated on January 17, 2024 by Manolis Maragkoudakis